THEORY

STAINLESS STEEL DRAINAGE SYSTEMS

To make a stainless steel drainage system for the food industry, it is necessary to follow certain guidelines::

- Choose the right material:: Stainless steel is the ideal choice for the drainage system as it is resistant to corrosion and chemicals used in the food industry. Grade 316 stainless steel is particularly suitable for environments with a high concentration of chlorides.

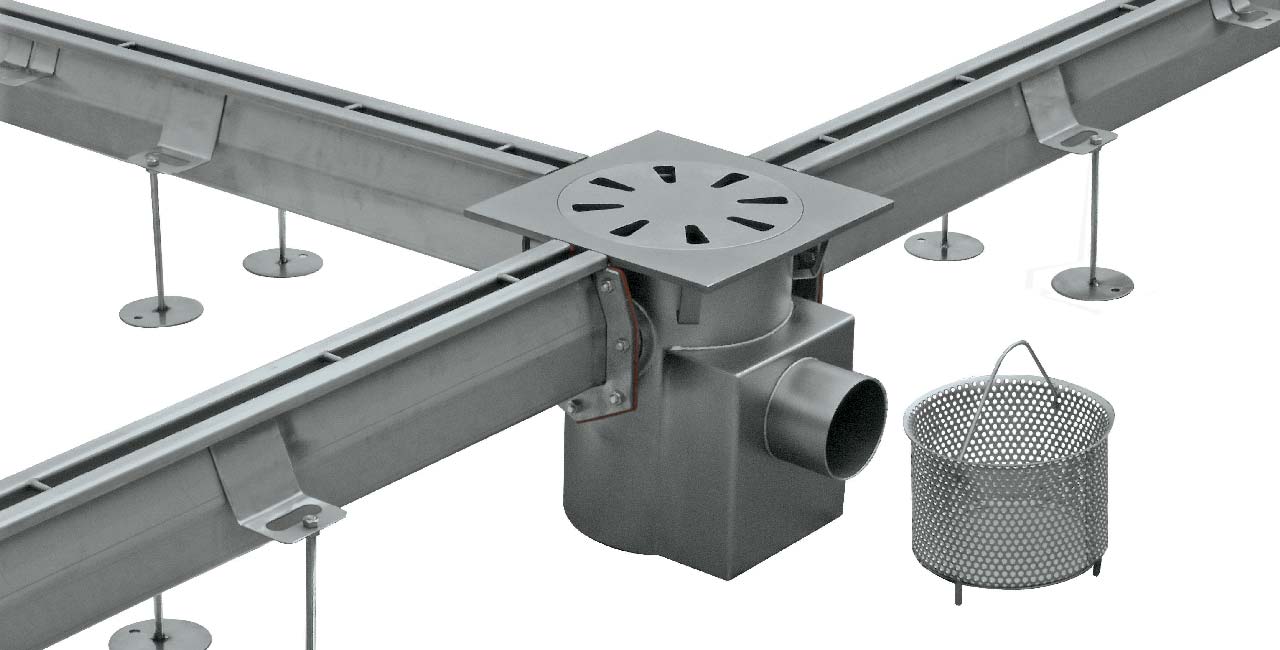

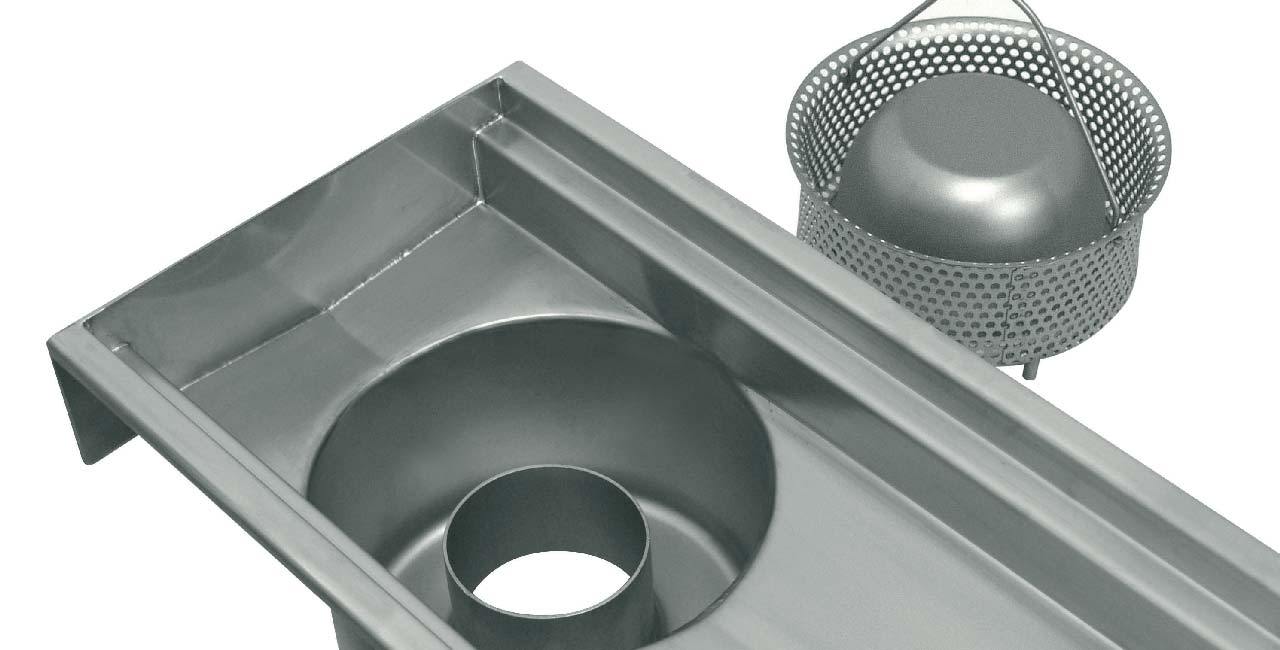

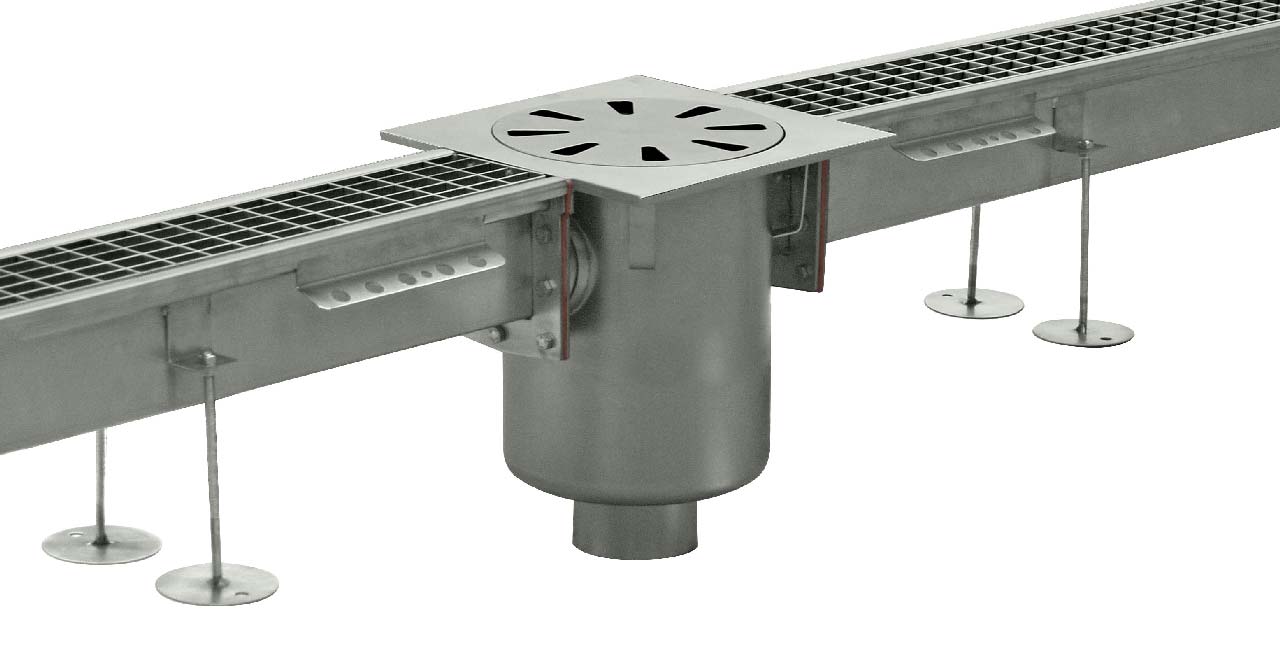

- Design a complete drainage system:The drainage system should include channels, pipes, fittings and drainage grilles. It should be designed in such a way as to ensure efficient and complete drainage of all areas of the surface to be cleaned.

- Choose the right dimensions:: The size of the channels and pipes should be chosen according to the type of liquid to be drained and the amount of flow. It is important to ensure that the drainage system can handle the amount of liquid that will be drained.

- Ensure food safety: The drainage system should be designed to prevent cross-contamination between the drained liquids and the foodstuff. It is important that all parts of the drainage system are easily removable and cleanable to ensure maximum hygiene.

- Ensuring ease of cleaningThe drainage system should be designed in such a way as to make cleaning and maintenance easy. The channels and drainage grilles should be removable and cleanable.

- Use professional installation:: It is important that the drainage system is installed by experienced and qualified personnel to ensure correct installation and a perfect seal.

- Use high-quality materials: All drainage system components should be manufactured from high quality materials to ensure maximum durability and resistance to corrosion and chemicals.

We offer a wide range of solutions, also customizable., to satisfy every needs.

Visit the page dedicated to drainage systems for the food industry

LEARN MORE

Contact us for more.