SERVICES

KLNKER TILES INSTALLATION

Since 1986, we have specialized in the supply and installation of high-quality industrial flooringà, using durable materials and that offer the best guarantees of durability and resistance. We offer a wide range of solutions for industrial flooring and coatings, including:

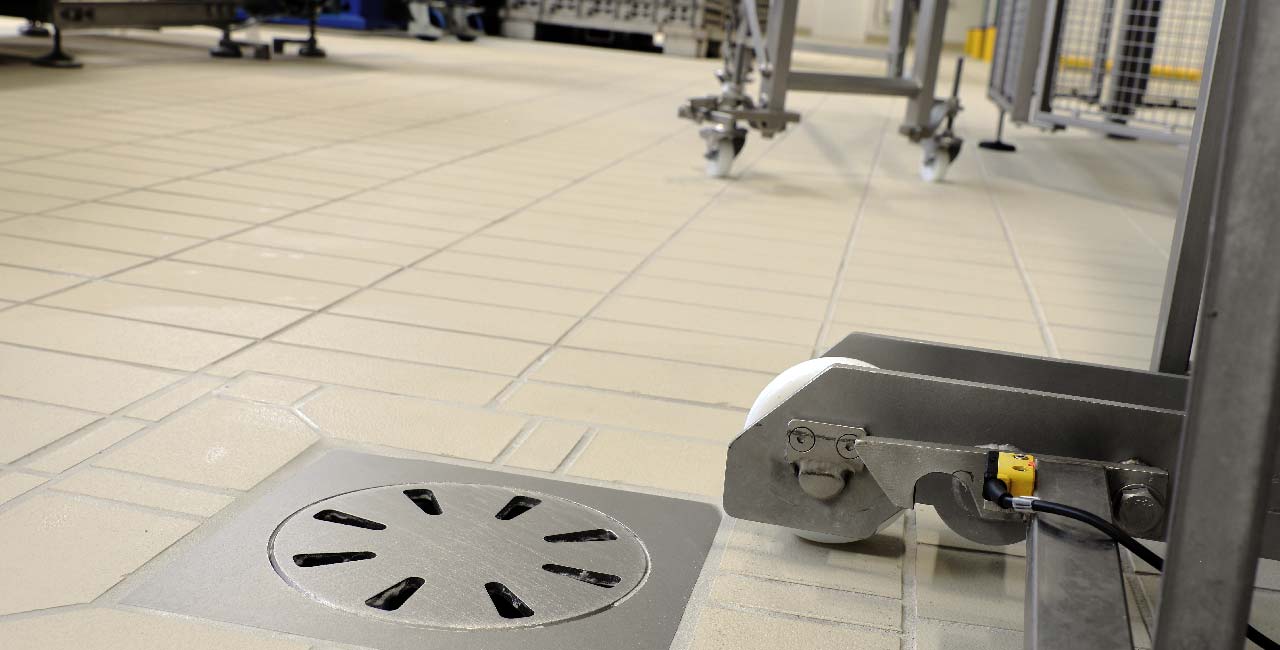

- Klinker tiles

- Drainage systems

- Epoxy resins

- Realization of certified cementitious screeds.

Discover the advantages of an industrial klinker flooring.

INSTALLATION IN A WORKMANLIKE MANNER

We supply and install High-quality klinker, german production, customizing the design according to the customer’s needs.

The correct installation of paving in klinker is essential to ensure maximum durability and safety over time.

PROFESSIONAL INSTALLATION

The installation of the industrial hygienic floor, must be carried out by highly specialized and qualified personnel, in order to guarantee an accurate and correct installation, of every single detail.

The laying quality of klinker depends on several factors, including:

- Experience and competence of the installer

- Quality of the material used

- Adequate preparation of the laying support

- Adhesion of the fixing materials

It is important that the laying is carried out following the the manufacturer’s specifications and current technical standards, ensure a durable and long-lasting installation.

.Thanks to our experience and attention to detail, we can guarantee an installation of klinker flooring of the highest quality; as evidenced by our prestigious references .

LAYING PREPARATION OF THE LAYING PLAN AND MORTAR

Even apparently minor operations then prove to be fundamental for the best success of flooring and cladding laying works. Interruptions of the portions of the cast or overlaps of the electro-welded mesh, when properly designed, allow the functions of the individual layers to be carried out to the best; also allowing the correct positioning of the tiles.

WIDE GROUT INSTALLATION

The classic 'wide joint' laying is a typical feature of some of the floor coverings we produce. This choice is mainly motivated by the our willingness to offer solutions:

- Free of all routine maintenance

- Offering the best guarantees of strength and durability.

The joint is the structurally weakest part of the 'floor system', especially where there is the passage of heavy loads such as forklift trucks.

Therefore, in order to ensure the massive durability of the floor under severe operating conditions and loads (as also specified by the manufacturers of drawn industrial klinker) we recommend a joint NOT smaller than 5 mm.

This allows the resin used for grouting, which is highly viscous, to disolate correctly within the joints, compacting them as best as possible and thus offering the best guarantee of mechanical resistance and impermeability of the floor, over time.

GROUTING

35 years of experience, even testing different types of resins, catalysts and inert materials, allows us today to immediately identify the best technical solutions.

The various products and their mixtures are defined on a case-by-case basis according to the various factors involved, including the intended use of the room, temperature and humidity during floor construction, joint width, tile thickness, etc.

In addition, experience and skills of the klinker industrial installersare essential to obtain perfectly orthogonal lines, such as a enhancement of the environments..

We offer three-component epoxy resins specifically formulated and chosen for the type of application and intended use of the different environments, whether processing, cooking or storage at high or low temperatures.

SITE ASSISTANCE

We pay maximum attention to each individual operational phasein order to ensure the best possible implementation of the planned activities, within the scheduled times and with the same quality with which we have built a solid reputation in over 35 years of activity.

Italbu offers the?experience of qualified personnel to carry out site inspections and estimates, when carrying out work of various kinds. By gathering data and details, we identify any critical issues, and then to coordinate the management of the work as best as possible, even where there are interventions by other companies.

SAFETY

Depending on the needs identified, we plan checks and inspections as early as the works estimate stageas well as during the subsequent implementation. This is also in order to comply with all safety requirements set by the competent authorities. We are ready to support your company in choosing the most suitable industrial flooring solution industrial flooring best suited to your needs.

LEARN MORE

Contact us to request a free and non-binding quote.